In the fast-evolving world of materials science, Prizmatem is emerging as a cutting-edge smart material with multifaceted applications. Designed with advanced optical, thermal, and structural properties, Prizmatem has attracted attention from industries ranging from aerospace and defense to consumer electronics and construction.

This article provides a detailed overview of what Prizmatem is, how it works, and why it’s gaining traction as a next-generation material in both scientific research and industrial development.

What is Prizmatem?

Prizmatem is a composite material engineered for high-performance applications where light manipulation, durability, and thermal stability are essential. Its name derives from the word “prism,” reflecting its unique optical characteristics, and “material element,” highlighting its function as a structural or functional component in engineered systems.

Though still relatively new to the public eye, Prizmatem’s development has been influenced by breakthroughs in photonic crystals, nanomaterials, and metamaterials. These advancements allow Prizmatem to bend, reflect, and transmit light in unconventional ways, making it ideal for use in high-tech devices, energy systems, and protective coatings.

Key Features of Prizmatem

1. Light Manipulation and Optical Performance

One of Prizmatem’s most notable features is its ability to manipulate light with extreme precision. This includes:

-

Controlled refraction and reflection

-

Selective light filtering

-

Color-changing effects under different angles (iridescence)

This makes Prizmatem suitable for applications in sensors, optical lenses, augmented reality (AR) devices, and decorative coatings.

2. Thermal and Environmental Stability

Prizmatem offers outstanding resistance to heat, UV exposure, and corrosive environments. These properties make it ideal for use in:

-

High-temperature industrial machinery

-

Aerospace and automotive surfaces

-

Outdoor construction materials

3. Mechanical Strength and Flexibility

Despite its advanced optical properties, Prizmatem does not compromise on strength. It is:

-

Impact-resistant

-

Scratch-proof

-

Flexible under stress, depending on its formulation

This enables usage in flexible displays, protective films, and wearable tech.

4. Sustainable and Energy-Efficient

Many versions of Prizmatem are made with low-energy manufacturing processes and can help improve energy efficiency in the systems where they are used. For example, coatings made from Prizmatem can reduce heat absorption, lowering cooling costs in buildings.

Composition and Structure

Prizmatem is typically a layered material, consisting of:

-

Nanostructured films that provide optical behavior

-

Polymer or ceramic matrices that give it strength and flexibility

-

Additives or dopants for enhancing conductivity, reflectivity, or durability

The combination of structure and material science enables Prizmatem to be tailored to specific applications. Some variants are transparent and flexible, while others are rigid and opaque.

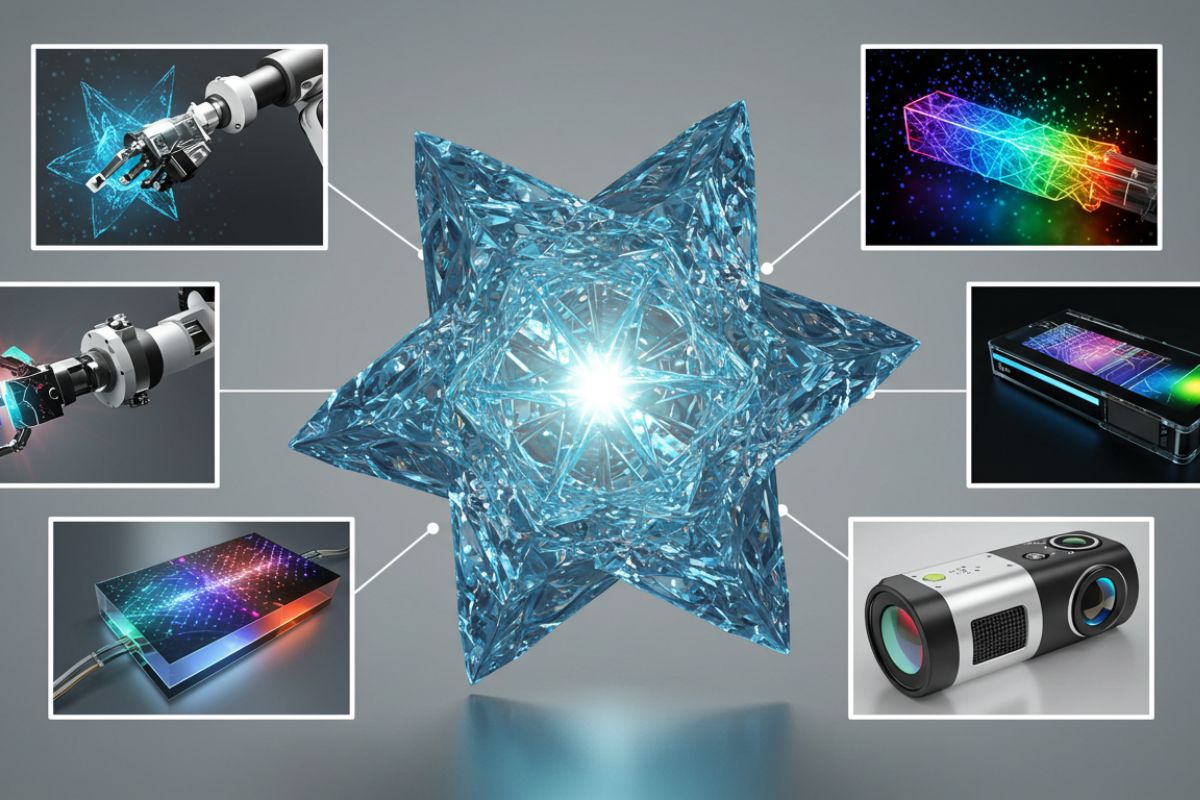

Applications of Prizmatem

1. Optoelectronics and Display Technology

Prizmatem’s ability to manipulate light with precision makes it valuable in:

-

OLED and LED display coatings

-

Augmented and virtual reality lenses

-

Laser-based sensors and optics

Its light-diffusing or focusing capabilities help enhance visual clarity and energy efficiency in these devices.

2. Green Building and Architecture

Prizmatem can be integrated into windows, façades, and roof materials to:

-

Reflect unwanted solar radiation

-

Let in natural light without heat buildup

-

Improve energy performance in buildings

This contributes to LEED certifications and other sustainability goals.

3. Aerospace and Automotive Industries

Due to its thermal resistance and structural integrity, Prizmatem is used in:

-

Heat shields

-

Surface coatings on aircraft and spacecraft

-

Lightweight, reflective vehicle parts

Its ability to survive extreme temperatures and mechanical stress makes it highly valuable in transport technologies.

4. Wearable Technology

Some variants of Prizmatem are both flexible and lightweight, perfect for:

-

Smart textiles

-

Wearable sensors

-

Biometric data collectors

These can be integrated directly into clothing or accessories.

5. Consumer Products and Aesthetics

Prizma-tem is also making waves in design and fashion due to its:

-

Iridescent appearance

-

Color-shifting ability

-

Durable finish

It is already used in premium packaging, automotive finishes, and high-end apparel for futuristic looks.

Benefits of Using Prizmatem

Versatility

Can be adapted for both aesthetic and functional use in multiple industries.

Performance Efficiency

Enhances durability, thermal management, and light optimization.

Eco-Friendliness

Many versions of Prizmatem support green manufacturing processes and help reduce energy usage.

Customization

Engineers can design specific versions of Prizma-tem for tailored optical or structural outcomes.

Challenges and Limitations

Despite its advantages, Prizmatem is still in the growth phase and faces some limitations:

-

Cost: Advanced materials like Prizmatem can be expensive to produce in bulk.

-

Scalability: Manufacturing techniques are improving but large-scale production remains complex.

-

Material Lifespan: Under certain conditions, long-term durability still needs to be tested across different industries.

However, ongoing R&D is addressing these issues, and breakthroughs are expected to bring down costs and enhance performance further.

Future Prospects

Prizma-tem is positioned to play a key role in the future of smart materials. With ongoing research in nano-optics, AI-driven material design, and biodegradable composites, we may soon see:

-

Transparent solar panels using Prizmatem layers

-

Smart windows that adjust tint based on sunlight

-

Advanced medical diagnostics via light-sensitive wearable sensors

The integration of AI with Prizmatem’s physical capabilities could also lead to self-adjusting surfaces, making it an essential part of smart environments and IoT-connected systems.

Conclusion

Prizmatem is more than just a material—it’s a technological platform for future innovation. Its ability to combine optical precision with physical resilience makes it a valuable asset across industries looking to innovate and optimize performance. As development continues, Prizma-tem has the potential to redefine how we design buildings, vehicles, electronics, and even clothing.